Technology

-

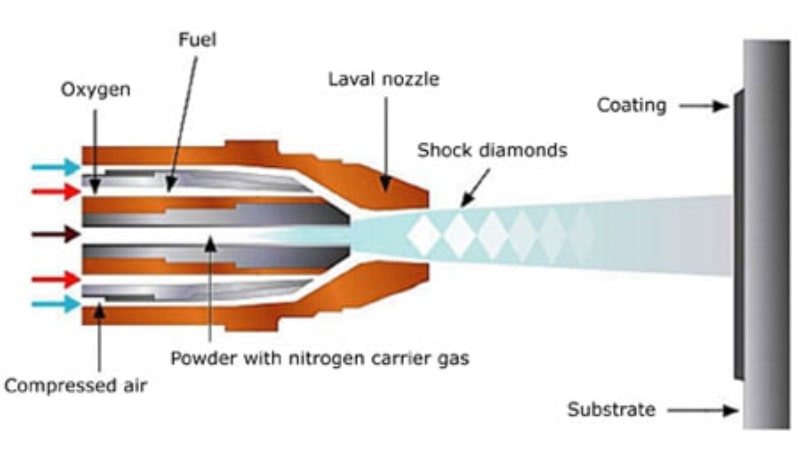

HVOF (High Velocity Oxy Fuel) is a thermal spray process with high-velocity, low-temperature spraying used for the production of carbide and metallic coatings. HVOF coatings are typically done for wear & corrosion protection of industrial components operating in harsh environment.

In HVOF process, carbide and alloy powders are fed into a combustion chamber where it is melted and accelerated to supersonic velocities. These semi-molten particles are deposited on substrate leads to rapid cooling to form a coating layer which has extremely high density & bond strength. HVOF provides mechanical bonded coatings which impart corrosion, erosion, abrasion and sliding wear resistant characteristics to the coated components.

ATS are technology specialists in HVOF process and provide wide range of coatings to suit specific applications & customer needs. We are backed by qualified and experienced team in our facilities to produce a wide variety of wear resist components to exacting standards with reliable, repeatable results.

-

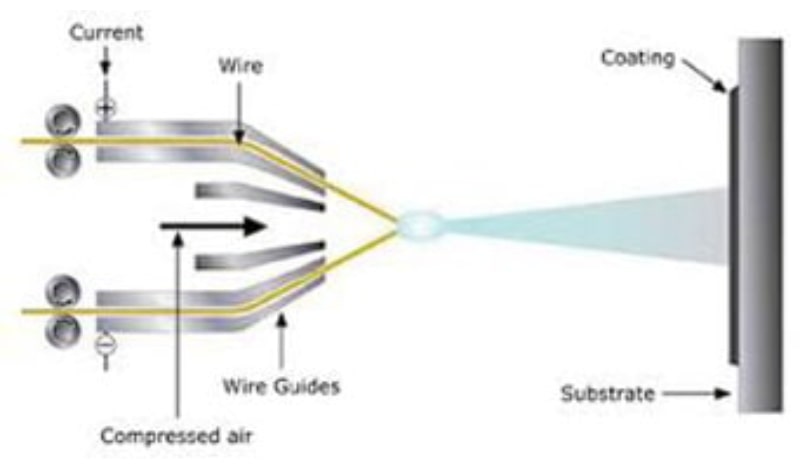

Wire arc spray is a variant of thermal spraying process where two conductive metal wires are fed independently into the spray gun. These consumable wires are electrically charged and an arc is generated between them when it comes in contact with each other. The molten material is atomized into small particles and propelled at high velocity onto the desired substrate by compressed air to form corrosion & wear resist layer.

ATS has expertise and proven track record for application of wire arc spray coatings for atmospheric & chemical corrosion. Over the years, we have developed customised coatings for components and equipment of Paper mill, Boiler, Petrochemical, Oil & Gas industries.

-

Flame spraying is a variant of thermal spray process in which the combustion flame used as a heat source to deposit powder or wire form of metals and alloys to form coating on substrate.

In ATS Metals and alloys such as molybdenum, aluminium, Zinc, copper, high carbon steel, stainless steel, bronze, brass, Inconel wires as coating materials in flame spray process. Similarly, Nickle & cobalt self-flux alloys powders, ceramic and abradable powders used in powder flame spray process.

-

Spray & Fuse process is a two step process where spraying done primarily followed by fusing of the sprayed material. This spraying is carried out by flame spray process. The spraying materials are self-flux alloys in powder form. Generally Self-flux alloys are alloys with low melting point of around 1,000℃, containing nickel and cobalt as base metal, boron and silicon as its fluxing materials.

Spray & fuse coatings can able to withstand in high impact load environment because of homogeneous & porosity free metallurgically bonded characteristics.

In thermal process only spray and Fuse coatings have a metallurgical bond with the base material while the other coating processes are limited to mechanical bonding.

In India ATS are the pioneers for spray and fuse coating of ROT rolls which are used in Hot Strip Mill of Steel plants.

-

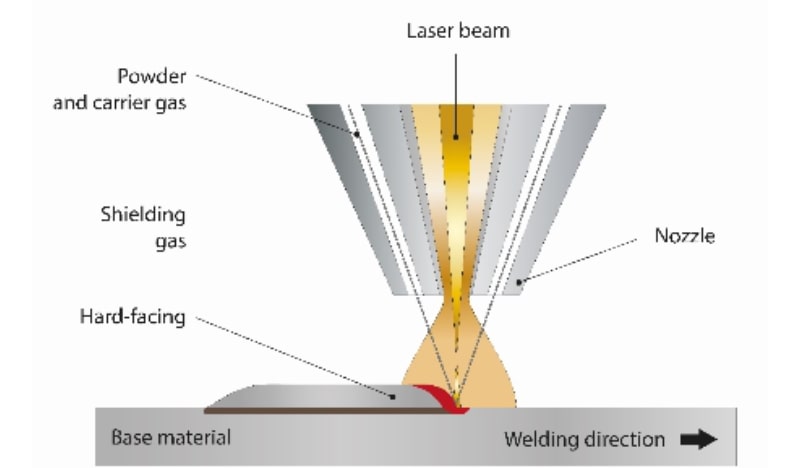

Hard facing is a process in which hard and wear resistant (tougher) materials will be welded on surface of a base metal to enhance surface wear resistance properties of the base metal to withstand harsh working environments.

In ATS Cobalt, Nickel and Iron base hard facing materials are deposited by GTAW, GMAW and SMAW processes.

Thermal Spray Coting

Thermal spraying is a technology which improves or restores the surface of a solid material. The process can be used to apply coatings to a wide range of materials and components, to provide resistance to: Wear, erosion, cavitation, corrosion, abrasion or heat.

What is Thermal Spray?

Thermal spray is an industrial coating process that heats or melts metallic or ceramic materials and deposits them onto a surface. It is used for surface enhancement or surface remanufacture.

How Does Thermal Spray Work?

Thermal spraying uses heat, depending upon the metallurgical properties of the coating material, and various carrier gases, depending upon the thermal spray process. Each process has different benefits as the result of these temperatures and process characteristics.

A thermal spray process should be carefully selected depending upon the desired coating characteristics such as; wear resistance, corrosion resistance, thermal barrier, and many more. Other factors include: size and shape, substrate material and the operating environment of the component. Each spray process has strengths and application limits.