Coating

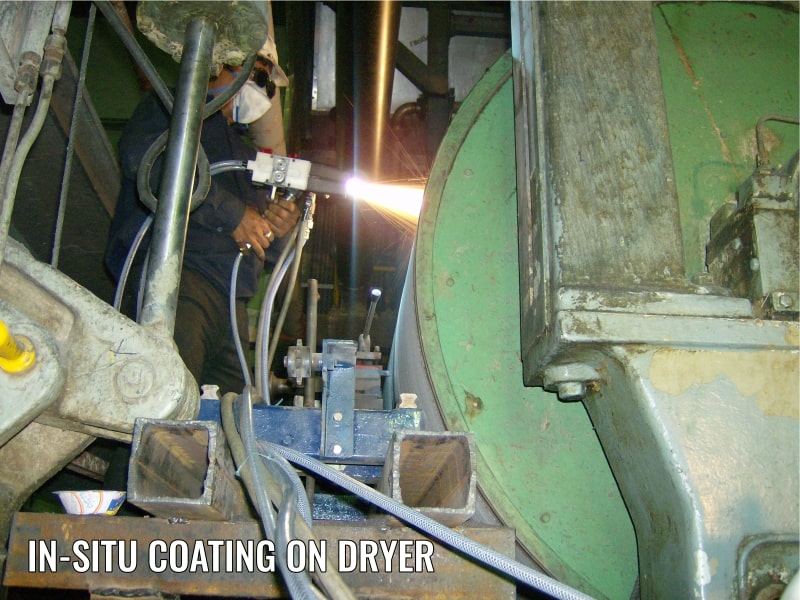

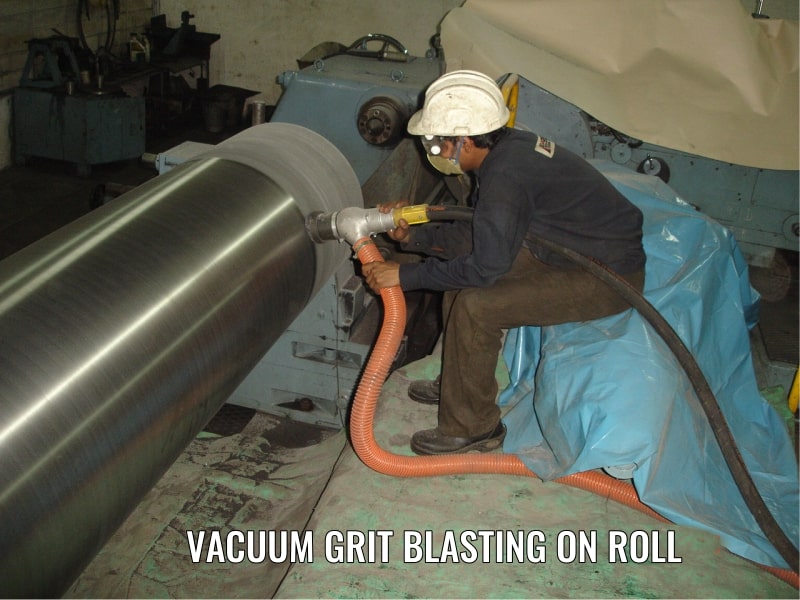

In the past 22 years we have provided surface coating and grinding solution on MG Cylinder, Dryer Cylinder, and Pope Reels, Head box, Pulp mill screws, spreader rolls and Rewinder drum. We have an excellent track record of on time job completion during shutdown periods of paper mills. Our large inventory of portable blasting machines, coating systems and traversing guides enable us to perform multiple onsite jobs simultaneously. We have Robotic facility to perform coating on Rewinder drum, calender roll, paper lead roll and many

MG Cylinder Coating

ATS has successfully completed 600+ Mg cylinder coating across the globe. ATS has advanced technology and specially developed Nano base material for coating on various paper grade manufacturing machines.

We measure the profile by a special Roll Profile instrument.

ATS have three patented technologies for MG cylinder coating.

ATSKOAT

- Specially developed for lower GSM paper manufacturing machines.

- Proven Technology for Tissue, Poster and OTC paper.

- It is nano base material which has excellent wear resistance properties.

- Hardness of coating is 55 to 60 HRC.

- Reduce re-grinding frequency

GLAZE COAT

- Kraft paper manufacturing machine.

- S.S base material with other patented material and binders which provide good life instead of traditionally SS coating.

ATG KOAT

- It is an economical solution for Lower GSM and Duplex board paper manufacturers.

- Able to retain the Glaze for a long time.

- Reduce re-grinding frequency.

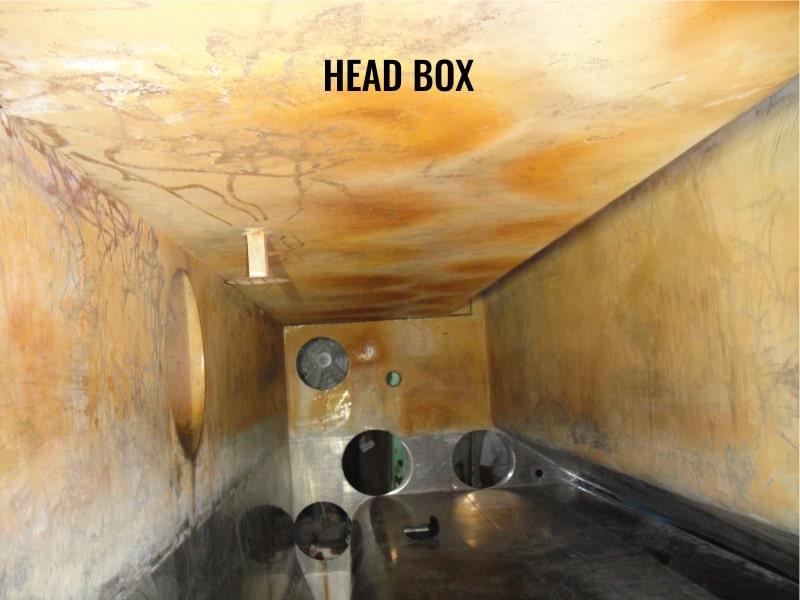

DRYER Cylinder

Each and every Dryer cylinder has a highly sticky starch and pigment stick/ deposit layer problem and due to layer reduction heat transfer and paper release property which is directly affected by paper gloss.

ATS has two solutions to overcome the problem.

- To do high chrome steel coating on the cylinder.

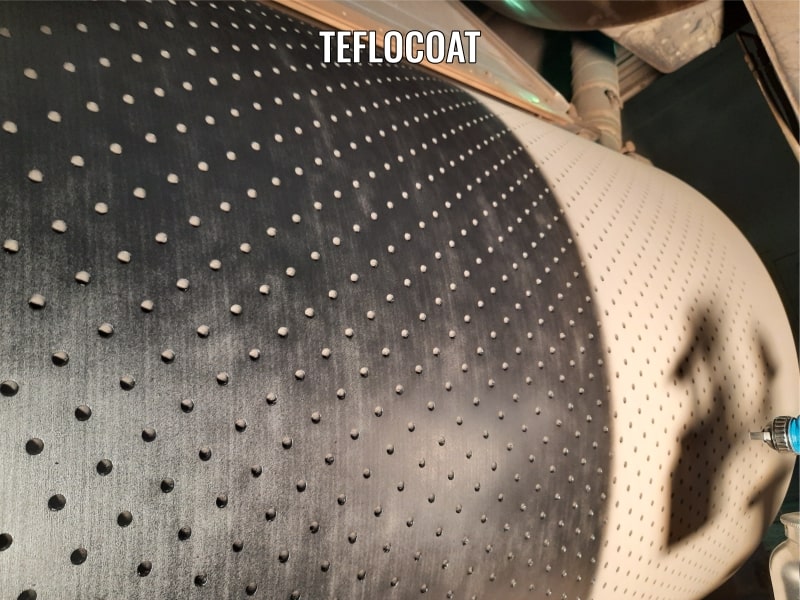

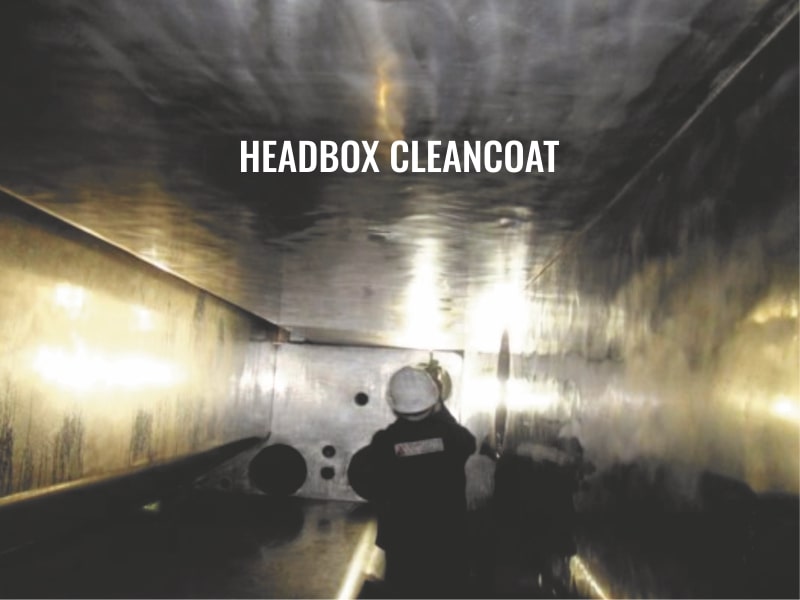

- Non stick TEFLOCOAT which is patented technology

TEFLOCOAT can be applied on After size press Dryer cylinder, Duo-Stabilizer Roll, Paper Lead roll.

Why choose TEFLOCOAT

- Best Non-stick properties against Starch and stickiness

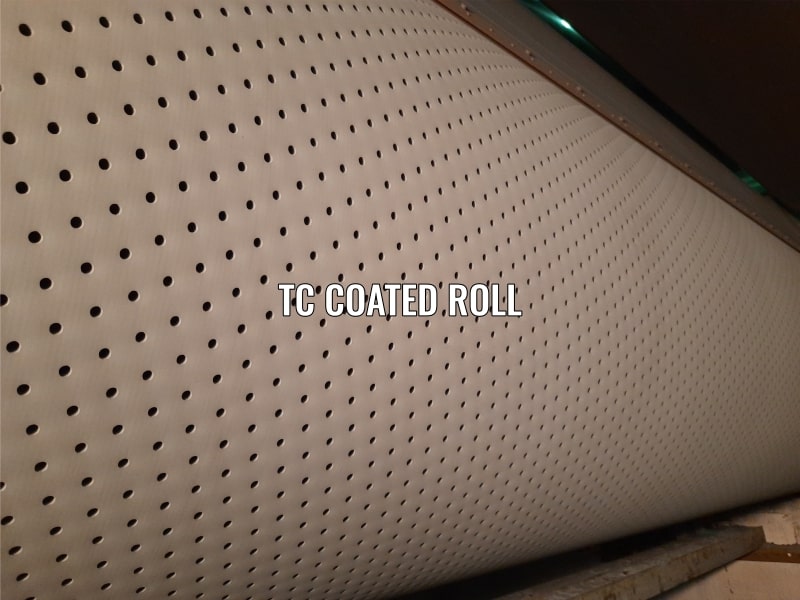

- Tungsten Carbide gives high hardness resulting in wear resistance against Doctor Blade

- Solve dirt problems on the dryer surface

- Improved corrosion resistance against moisture

- Heat transfer characteristic in actual condition

- Improve machine running and increase all around efficiency

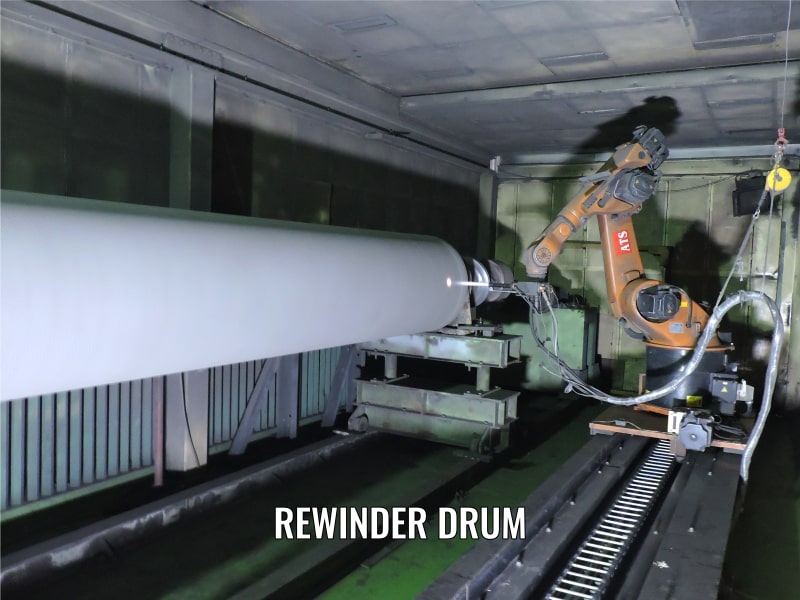

Rewinder Drum & Pope Reel

Rewinder Drum & Pope Reel are functions of Reel the paper with high gripping. If the roll surface roughness is gone then occurs slippage. ATS has developed GRIPCOAT coating material which is excellent suitable for Rewinder drum coating.

We undertake the rewinder drum coating in acoustic Robotic HP/HVOF coating process at the Workshop as well as have a special jig and fixture to undertake the work at the customer site.

Why Choose GRIPCOAT

- Suitable / Proper roughness value avoiding Slippage

- 1/20 lesser wearing compared to Cast steel roll/ stainless steel

- Uniform Coating thickness provides uniform winding

- Enables users to increase machine speed

- Improve flattering in the printing process (mainly for high speed machine)

- Reduce maintenance of the pope reel

- Rise in productivity and overall efficiency

- High hardness of the coated material results in retention of evenness of the surface for a longer time

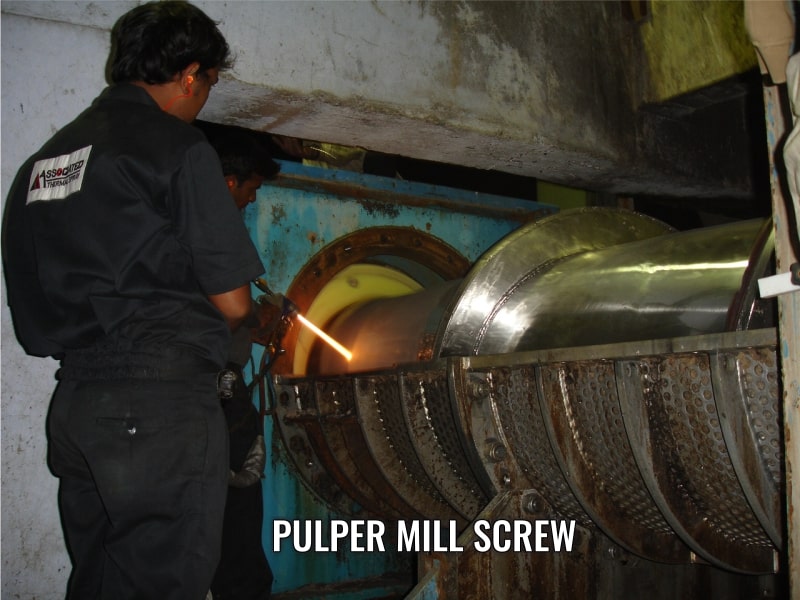

Components coating

ATS have developed many coating materials with special jigs and fixtures to undertake coating on various components at site as well as ATS shop.

We are doing coating on below components

- Pulp Mill screw

- Pulp Mill Washer

- Press Roll

- Paper Lead roll

- Hard chrome plating on roll