About Us

Experience

Welcome To ATS Techno Limited

Established in the year 1992, ATS has established itself as one of the leading manufacturers and exporters of Thermal spray services like Metal spray coating, HP/HVOF coating, Plasma coating, and many precision machinery parts with protective coating as per clients requirement. Our entire range of products is widely trusted for its efficiency, ability to withstand high temperature & pressure, and wear resistance. Apart from this, we are also engaged in providing Surface Engineering Services to our clients. These services are intended to protect the expensive machines from surface damage in order to enhance the life of the machines and reduce maintenance costs.

Quality has been our prime priority throughout our operations. We have a team of highly skilled professionals, who have all the skills and expertise to offer world-class Surface Engineering Services to our clients. These professionals provide a wide range of on-site services like restoring, refurbishing, repairing, overhauling, and coatings for all kinds of rotating or reciprocating machinery.

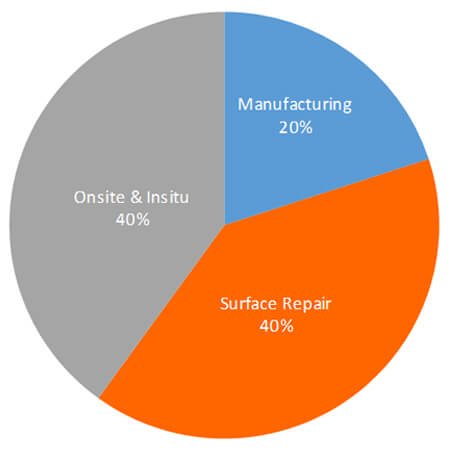

MANUFACTURING LONG-LIFE COMPONENTS

ATS manufactures machinery parts and components with innovative metal coatings. These specially engineered coatings impart extended service life to the component by retarding the damaging effects of industrial wear factors such as erosion, corrosion, cavitation, friction, sliding wear, oxidation. The long-life products from ATS find wide application in Steel, Chemical, Hydro Turbine, Steam Turbine, Oil Exploration and Oil Refining industries.

REPAIRS, RECLAMATION & REFURBISHMENTS

ATS aims to improve the working life of Process Equipment , Metal Structures , Machinery parts & components that are in service.This is done by providing surface damage solutions through various surface modifications methods including machining, grinding and metal spray coatings.

COATINGS BY THERMAL SPRAY TECHNOLOGY

For manufacturing and refurbishing activity we utilize Thermal Spray Technology on Process equipments, metal Structures, Machinery parts & Components. Thermal Spraying increases the service life of the product by reducing the damaging effect of industrial and environmental wear factors. Flame, Wire Arc , HVOF and Plasma Spray processes are implemented for undertaking metal coatings.

- Component Manufacturing Rolls-Shafts-Steam Turbine Components

- Surface Repair Rolls-Cylinders-Turbine Components

- Onsite & Insitu Coatings Tanks-Vessels-Reactor-Heat Exchanger-Boilers

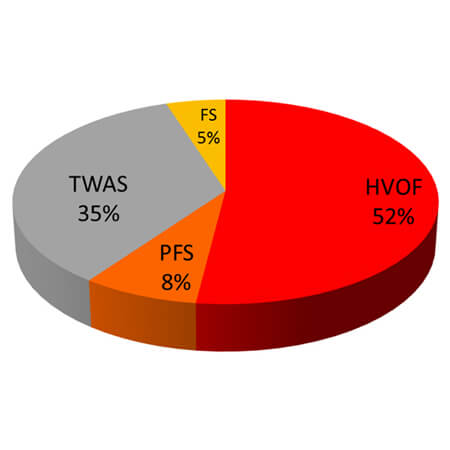

SEGMENT WISE DETAILS

- HVOF (High Velocity Oxy Fuel) Tungsten Carbide-Nickel Chrome-Stellite-Chrome Carbide

- TWAS (Twin Wire Arc Spray) High Chrome Steel-Copper-Bronze-Zinc-Aluminium-Molybdenum

- Flame Spray High Chrome Steel-Copper-Bronze-Zinc-Aluminium- Molybednum

- Powder Flame Spray (Spray & Fuse) Self Fluxing Alloys

TYPES OF THERMAL SPRAY COATING SYSTEM