Experience

Welcome To ATS Techno Limited

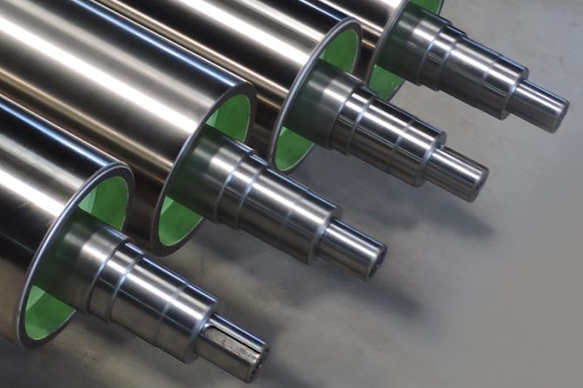

Established in the year 1992, ATS has established itself as one of the leading manufacturers and exporters of Thermal spray services like Metal spray coating, HP/HVOF coating, Plasma coating, and many precision machinery parts with protective coating as per clients requirement. Our entire range of products is widely trusted for its efficiency, ability to withstand high temperature & pressure, and wear resistance. Apart from this, we are also engaged in providing Surface Engineering Services to our clients. These services are intended to protect the expensive machines from surface damage in order to enhance the life of the machines and reduce maintenance costs.

Quality has been our prime priority throughout our operations. We have a team of highly skilled professionals, who have all the skills and expertise to offer world-class Surface Engineering Services to our clients.

Read MoreExplore Our Products

WHY CHOOSE US

One Stop Shop

Commitment To Excellence

International Quality Standards

Technical Assistance

Total Customer Satisfaction

More Than 32 Years Of Trust

Advanced Technology and Equipment

Global Presence

Industries WE SERVE

Technical Collaboration