Skirt & Hood

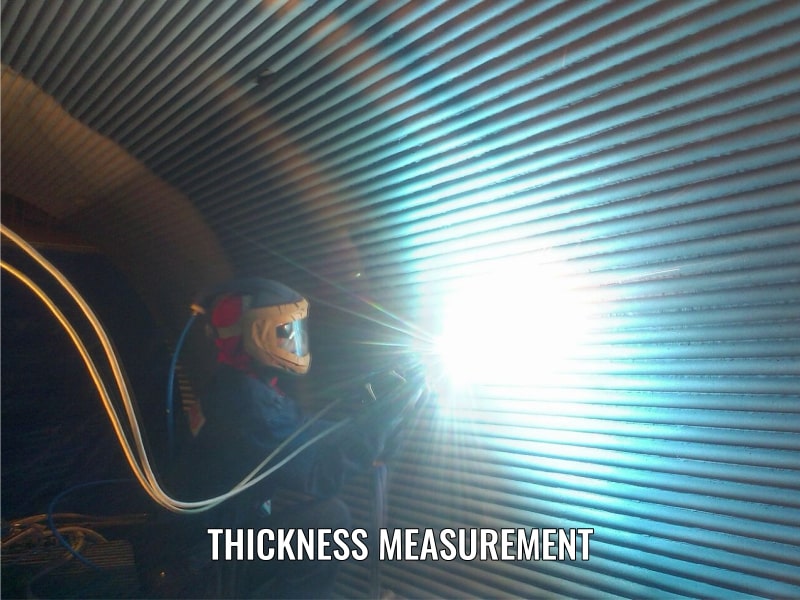

In-situ coating

There is metal wastage on the inside area of the stack (tube surface) due to continuous heat, humidity, atmospheric moisture, thermal shock, presence of sulphur & the dust particle movement.

This surface deterioration will reduce tube wall thickness which will necessitate replacement. The high cost of new tube replacement can be prevented by application of erosion resistant coatings on tube surface area.

ATS has developed the application of a special alloy coating by use of thermal spray technology for retarding metal wastage on tube surface in skirt & hood zone of steel melting shop. This coating job has been successfully completed by our company in a compact time span during shutdown period.

Coating Inside:

- Movable Hood Tubes (Lower Stack)

- Fix Hood Tubes (Upper Stack)

- Swivel Elbow (Gas Base)

Features

- Excellent coating hardness at elevated temperature

- Excellent Wear and Erosion resistance

- High Thermal conductivity

- Lowest co efficient of friction

- Superior bond strength